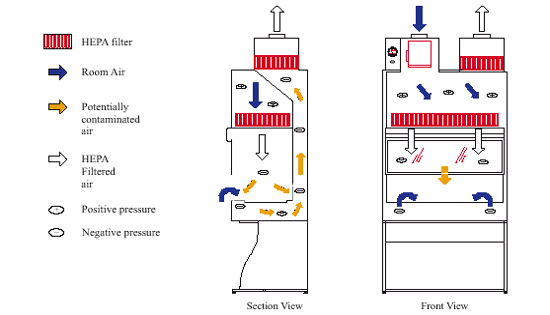

Laminar Flow Cabinets create particle-free working environments by projecting air through a filtration system and exhausting it across a work surface in a laminar or uni-directional air stream. They provide an excellent clean air environment for a number of laboratory requirements.

Laminar Flow Cabinets are suitable in the following sectors.

The process of laminar air flow can be described as airflow where an entire body of air flows with steady, uniform velocity.

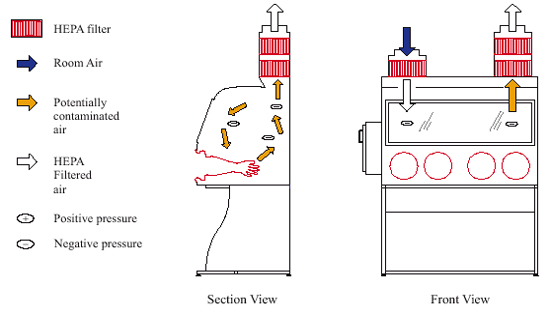

Laminar Flow Cabinets work by the use of in-flow laminar air drawn through one or more HEPA filters, designed to create a particle-free working environment and provide product protection. Air is taken through a filtration system and then exhausted across the work surface as part of the laminar flows process.

Commonly, the filtration system comprises of a pre-filter and a HEPA filter. The Laminar Flow Cabinet is enclosed on the sides and constant positive air pressure is maintained to prevent the intrusion of contaminated room air.

Laminar Flow Cabinets can be produced as follows.

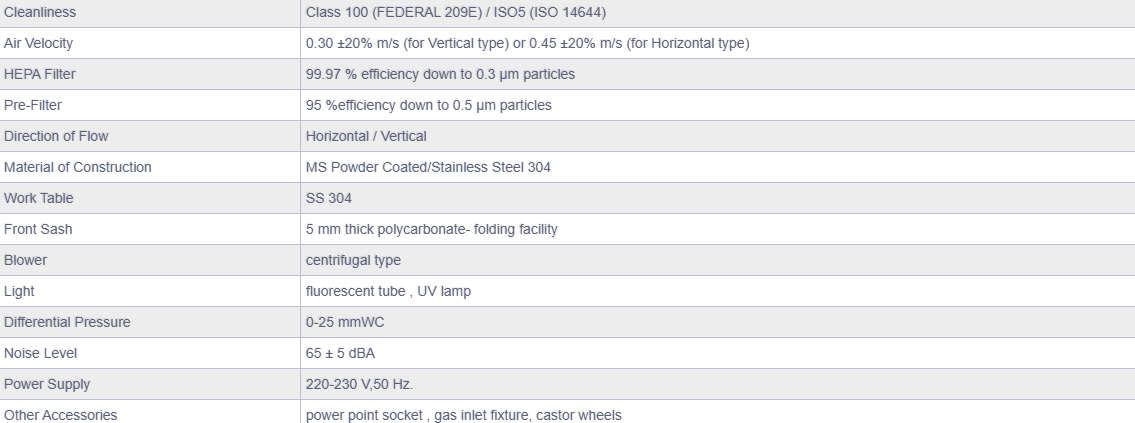

Horizontal Laminar Flow Cabinets receive their name due to the direction of air flow which comes from above but then changes direction and is processed across the work in a horizontal direction. The constant flow of filtered air provides material and product protection.

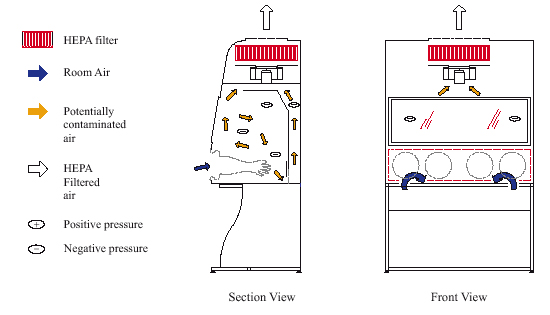

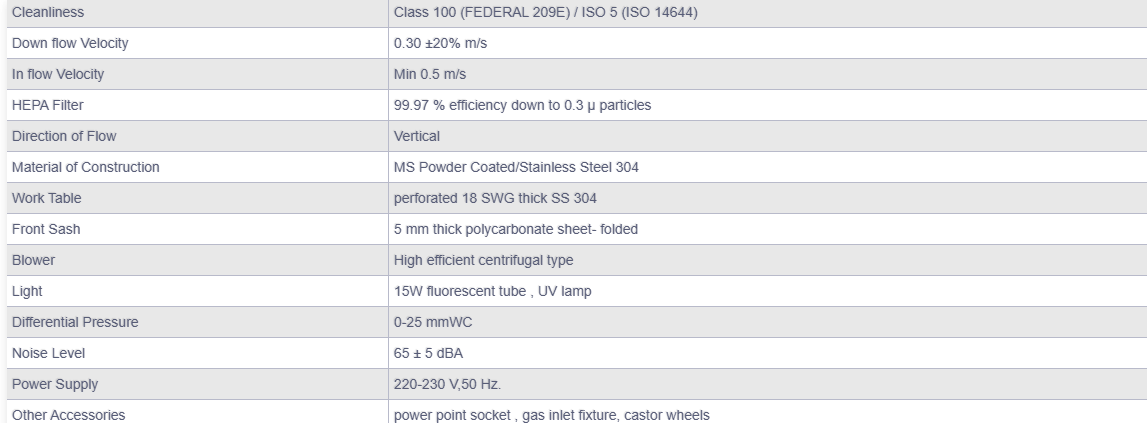

Vertical Laminar Flow Cabinets function equally well as horizontal Laminar Flow Cabinets with the laminar air directed vertically downwards onto the working area. The air can leave the working area via holes in the base. Vertical flow cabinets can provide greater operator protection.

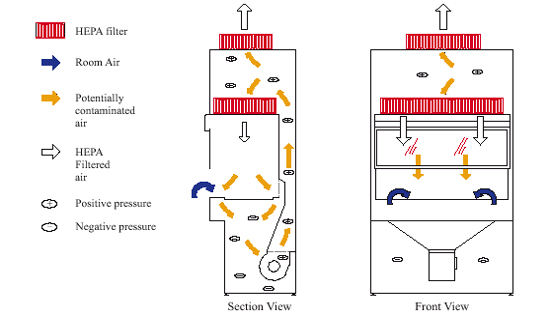

Biological Safety Cabinets safeguard users, materials and the environment from aerosol hazards and other types of environmental contamination.

They are utilized by a wide range of scientific, research and development organizations within both the commercial and non-commercial sectors, including pharmaceutical, medical, clinical research, defense, education and general healthcare sectors.

There are three classes of BSC: Class I, Class II and Class III. Selection of the proper class of BSC requires careful evaluation of the activities to be carried out. Laminar Flow Cabinets or other clean benches that direct air towards the operator are not biological safety cabinets and must not be used for handling infectious, toxic or sensitizing materials.

These cabinets have non-recirculated airflow away from the operator that is discharged to the atmosphere after filtration through a HEPA filter. They provide good operator protection but do not protect the product within the cabinet from contamination.

Class II cabinets are designed for personnel, product and environmental protection. They are designed for work involving microorganisms and are divided into two types (A and B) on the basis of construction type, airflow velocities and patterns, and exhaust systems(4).

Within type (A), there are two subtypes, A1 (formerly designated type A) and A2 (formerly designated type B3). Within type (B), there are two subtypes, B1 and B2. Class II cabinets are most commonly used in biomedical research laboratories because of their characteristics.

Class III cabinets are totally enclosed and gas-tight with HEPA filtered supply and exhaust air. Work is performed with attached long-sleeved gloves. The cabinet is kept under negative pressure of at least 120 Pa and airflow is maintained by a dedicated exterior exhaust system. Class III cabinets protect the worker and the product. The exhaust air is double HEPA filtered or treated by HEPA filter and incineration. Removal of materials from the cabinet must be through a dunk tank, double door autoclave or air-lock pass-through for decontamination.

Dispensing / Sampling booths are used for filling, refilling, weighing & sampling of Raw material & Components

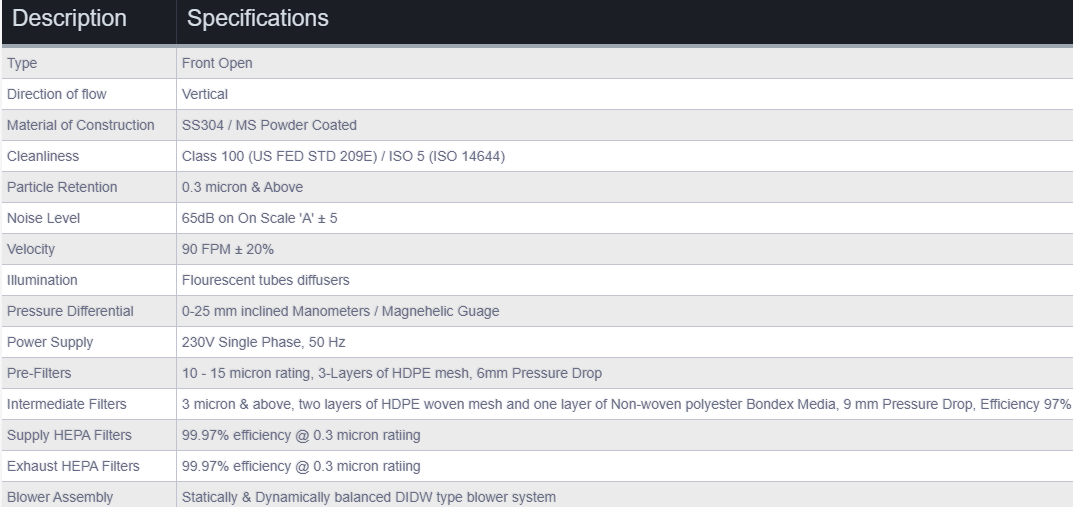

Booths are designed to give mixed air flow stream for product, operator and environmental protection and used to control the hazardous emissions of dust powder during powder dispensing / sampling process. 0.3 micron downward air stream deflects air-borne dust away from the operator breathing zone which is caused in handling operation. Dust particle available is being filtered at three levels of filtration prior to being circulated back to the booths air stream. It is applied for fine filtration in air conditioning & ventilation system, suction air filtration in compressors etc.

A fume hood is a type of local ventilation device that is designed to limit exposure to hazardous or noxious fumes, vapors or dusts. A fume hood is typically a large piece of equipment enclosing five sides of a work area, the bottom of which is most commonly located at a standing work height.

Fume Hood is available in 4', 5', 6' and 8' widths