An Air Handling Unit (most of the times abbreviated to AHU), or Air Handler, is a central air conditioning station that handles, supplies and circulates air into the required working zones through ventilation ductwork . Handling the air means that the air will be delivered with thermo-hygrometric and IAQ (Indoor Air Quality) treatment. Basically, air is treated through a set of processes like filtering, cooling and/or heating, humidifying and/or dehumidifying in accordance with the specification of respective projects (Pharmaceutical plants, Hospitals, Laboratories, offices, schools etc).

CADILLAC strives to deliver state-of –art AHUs with accurate design & efficient features to suit the industrial as well as corporate requirements.

Fresh Air type AHU- handles only fresh filtered air and can’t control Temperature & RH

AC/ HVAC type AHU- delivers Temperature & Relative Humidity controlled filtered air

• Frame Work :- AHU frame work is constructed from hollow extruded aluminum profiles anodized or power coated. In critical cases thermal break profile can be selected. The frame works are held by corner joints and omega joints.

• Panels :- AHUs are offered both in Single Skin & Double skin. Generally, Single Skin is used for fresh air type project. Panels are constructed by GI or aluminum or SS sheet. Double skinned panels are made in various thickness (25 mm, 30 mm, 50 mm) which are insulated by Polyurethane Foam (PUF) (density 36 ± 4 kg /m3) or expanded polystyrene sheet (density 26 to 40 kg/m3). Phenolic insulation is also available as per customer requirement. Special epoxy paints are done on inside part of panel for anti corrosive effect. Inside part can also be covered by perforated sheet for acoustic insulation.

• Filter Chamber :- CADILLAC make air filters like Pre Filter (efficiency-90% @ 10 micron), Fine Filter (efficiency-95% @ 5 micron) and /or HEPA Filter (efficiency-99.97% @ 0.3 micron) are used to purify the air.

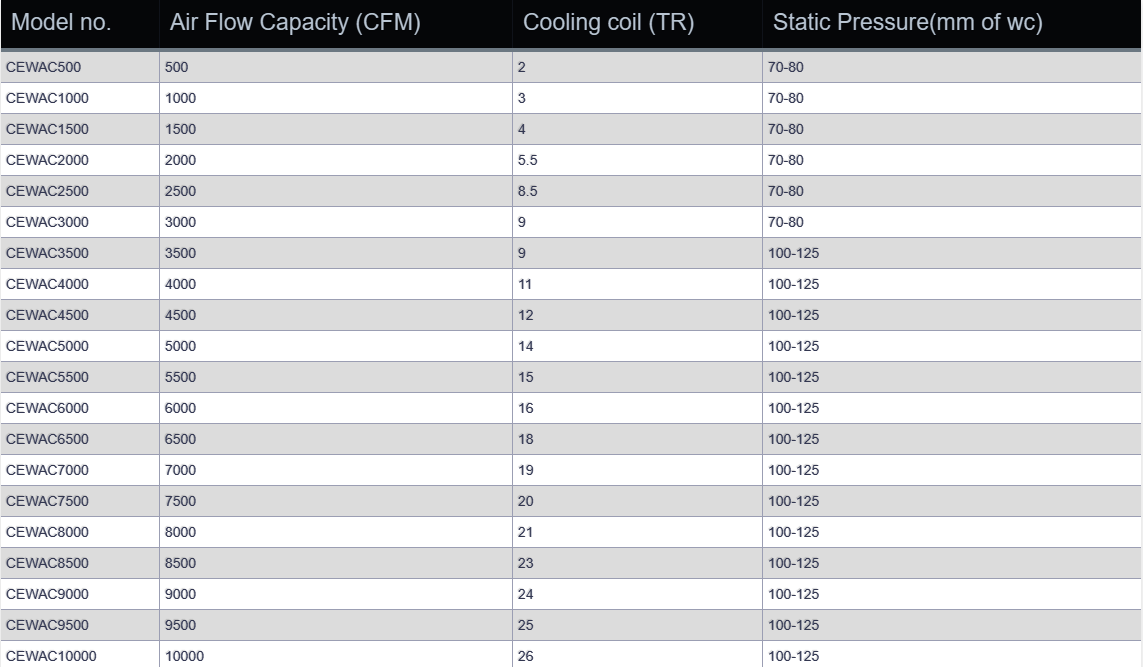

• Coil Chamber :- Cooling Coils and/or Heating Coils are used to control the Temperature and/or Relative Humidity of air. Coils are manufactured of good quality of copper tube having Aluminum Fins for better heat transfer. Capacity of Cooling coil ranges from 2 to 26 TR (for DX type).

• Fan Chamber :- Highly efficient forward or backward curved SISW or DIDW fans are used to deliver the air in the room. Air flow capacity ranges from 1000 cfm to 30,000 cfm and static pressure from 70 to 125 mmwc. All fans are individually tested and dynamically as well as statically balanced for smooth & noise free operation. Fan and Motor are mounted on slide rail & vibration isolator for easy adjustment of belt tension.

• Mixing Chamber :- In order to mix returned air with fresh air, air mixing chambers are provided.

• Drain Pan:- Drain pan made of S.S-304, Aluminium or G.I ensures proper drainage of condensate.The Drain Pan with a proper slope assures quick & complete water drainage.

Why to choose CADILLAC AHUs ?

Applications of AHUsM